Rotoplastic was born with the intention of bringing product and process innovation to the market of rotational molding machines for plastics. The company choice was to orient itself, from the outset, to create machines that could be integrated into complex, cutting-edge production structures and organized with a view to "industry 4.0". As for product innovation, where we have unhinged the paradigms of the last twenty years, also in the technological implementation of processes, we work having as a reference point the operator who will have to manage our machines and the structure that will have to integrate them into the internal of larger and more complex production cycles. In concrete terms, this means having a technological DNA and attention to the component of experience and expertise of the operators, putting them in a position to better manage the potential of the systems we install.

The guiding concept of industry 4.0, or the idea of the "smart factory", is shared by the Rotoplastic design team. In fact, our goal is to install machines capable of:

> produce useful data to optimize its operation in real time > share information with the entire company IT network (from machine workstations, management systems, work scheduling systems > archive the data in a database accessible at any time, even remotely > make data management and machine programming flexible

These 4 points meet the guiding criteria for the implementation of the "smart factory": Smart production: new production technologies that create collaboration between all the elements present in the production or collaboration between operator, machines and tools; Smart service: all the "IT infrastructures" and techniques that allow systems to be integrated;

Smart energy: technologies created to optimize energy consumption, creating more performing systems and reducing energy waste How do we manage to achieve these results? Through a modern design, in which the realization of the machine is considered as a whole, knowing the structures of the companies in which we will install our systems, communicating with the Customers to customize the machines according to their needs, their production lines, their specificity. Our goal is not to eliminate the presence and role of operators on board the machine, but to provide them with all the information that can assist them in planning and managing the company's production capacity, with systems designed and built to be the as efficient as possible, reducing energy consumption and limiting polluting emissions. The wealth of data that our machines generate, collect and make available, thanks to the software developed entirely in Rotoplastic, makes it easy to use this information, share and process it.

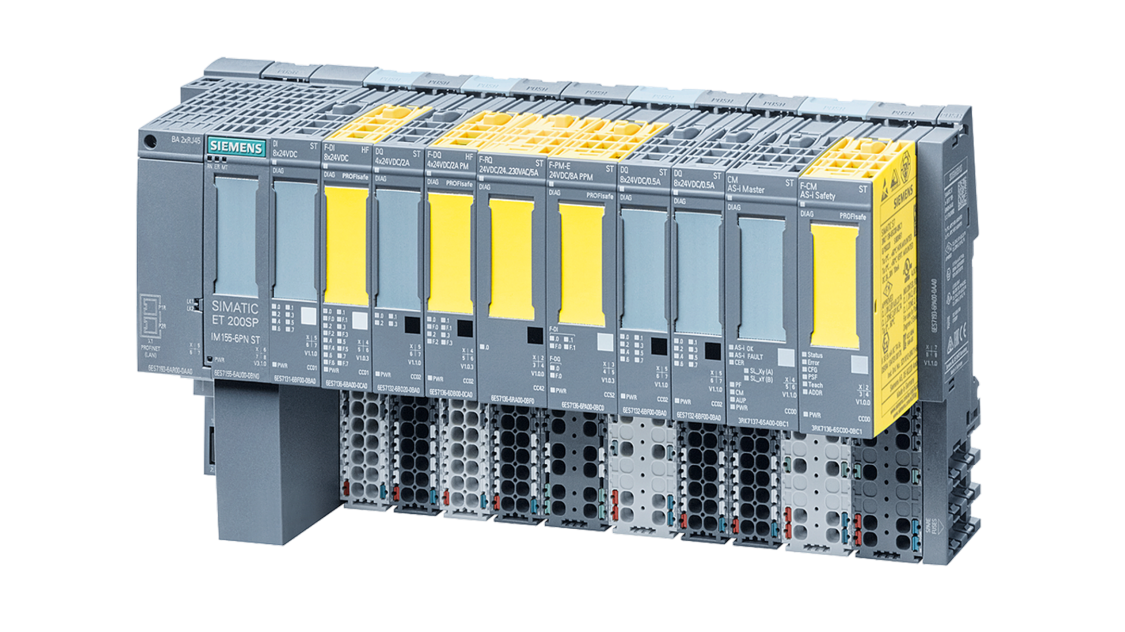

Furthermore, to optimize the digitization process and prevent the typical failures of traditional machines in which electromechanics for components is still predominant, we have chosen to eliminate it from all the elements in which digital technology could replace them (keyboards, connections ...) to get two benefits: longer life cycle of components and therefore fewer assistance interventions; generation and acquisition of information that the use of digital solutions allows to obtain. In this way, using advanced systems such as Siemens installed on our plants, the communication between the different elements that make up the machine is almost total.

It is possible to read and write any device of the machine directly on the network, using the Profinet protocol. For example, we can interface in real time with the inverter, the control package of the pneumatic valves, the photocells for reading the status of the emergency mushrooms. From the inverter we can get information not only about how much power is absorbed during the work phase, but how much energy is used, rather than the correctness of the power supply voltage; it is also possible to measure and verify in real time the energy produced by the inverter itself or the energy regenerated by the system, which in the event of a slight imbalance of the arm, redistributes in the network. The implementation, right from the design phase of mechanics, electronics and software, allows Rotoplastic to produce machinery for rotational molding of plastic materials, extremely efficient from the point of view of productivity, effective in energy yield and easily integrated into more modern and digital production lines.