Continuous Development

Rotoplastic continues the evolution of rotational moulding machines. The goal is to create competitive and high quality machines.

HIGH QUALITY HIGH PRODUCTION LOW CONSUMPTION

Dalla parte del produttore e dell’ambiente.

Costruite con le più nuove tecnologie le nostre macchine hanno una qualità superiore e sono progettate per aumentare la produttività diminuendo i consumi, meno sprechi maggiore attenzione ai costi e all’ambiente. La struttura è realizzata con profili metallici e pannelli di coibentazione ad alta efficienza.The insulating panels are made of high-strength steel sheets, the insulation is composed of mineral fiber made with wet-felt technology and ceramic fiber with a limit temperature [° C] 1100 for a total density of over 180 kg/m³.

Per garantire un eccellente isolamento termico lo spessore totale dei pannelli isolanti è di 115mm. Infatti, quando la temperatura di funzionamento all’interno del forno raggiunge i 330°C, esternamente le pareti non superano i 40°C (con temperatura ambiente di 25°C).

Thanks to our speed control algorithm connected to the chamber pressure and the air temperature, the ventilation of the air in the molding chamber is dimensioned with electrical powers that are 70% lower than the old generation machines, our system has allowed us to use a parallel axis gearmotor so as to completely eliminate power losses on the transmission, thanks to the high efficiency inverter and the IE3 motor, electrical consumption is minimized our control system allows to reduce the total electricity consumption of the molding chamber by an average of 50% on the lower hourly average of machines of the same series produced to date.

Why choose Rotoplastic

Greater productivity, technology, lower consumption and harmful emissions

High-level axis control

The exclusive use in the world of products of new technology and high performance, power and control.

Not just heating

Rotoplastic designs and builds the best solutions for cooling the mould in the rotational field

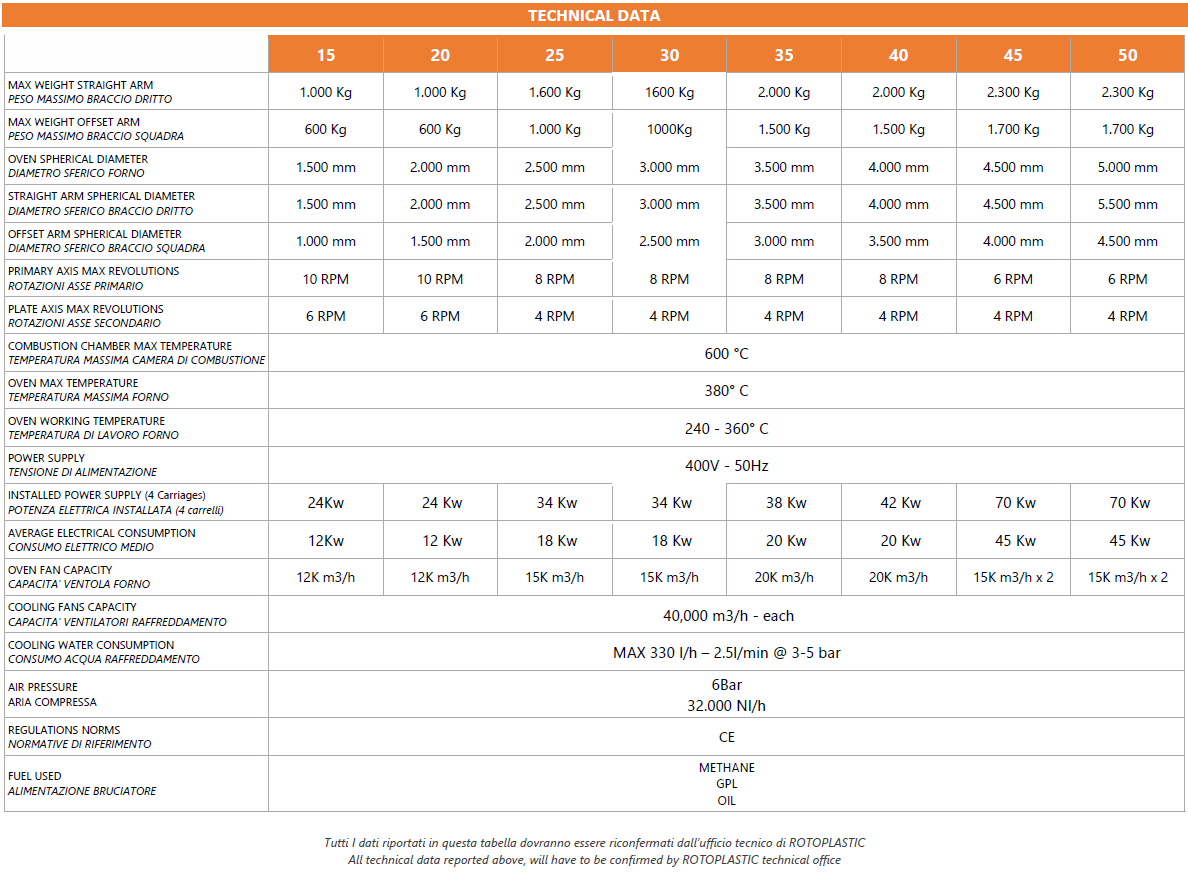

Mechanical design

Entirely designed by us with an industrial production process, our mould holder arms are innovative and extremely robust

FROM DESIGN TO PRODUCTION

Producing machines is not enough We need to know and control technology

THE BEST OF TECHNOLOGY

Entirely designed by us with an industrial production process, our mould holder arms are innovative and extremely robust

Booms with high capacities and unmatched technology! The motors are all IE3 according to the European directive 2005/32/EC.

The nominal frequency of the gearmotors is 87Hz which, thanks to the new Motec 8400 inverters, allows energy savings of 30% less than machines of the same size.

The motors are controlled via the high-speed Profinet field bus, the Profinet system allows you to obtain the instantaneous absorbed current and optimal management of the speed from the inverter.

Thanks to an encoder, the axis speed is precise and linear regardless of the load, this allows the elimination of motor sliding and an accuracy comparable to positioning systems with synchronous motors.

Rotoplastic

Producing technology beyond imagination